|

|

|

Product Details:

Payment & Shipping Terms:

|

| Inlet And Outlet Port Size: | 1/2'' | Material: | Aluminum Alloy |

|---|---|---|---|

| Noise Level: | Low | Power: | 2.2KW |

| Pressure: | High | Speed: | 1450rpm |

| Type: | Rotary Vane Pumps | Vacuum Degree: | High |

| Voltage: | 220V | Warranty: | 1 Year |

| Weight: | 7kg | ||

| Highlight: | ISO Rotary Vane Pumps,Flexible Rotary Vane Pumps,Multipurpose Desiccant Air Dryer |

||

ATLAS COPCO CD20+-335+ -70°C DESICCANT AIR DRYERS AIR TREATMENT

CD 20+-335+

Cerades™ efficiency & continuous operation

1, Cerades™

The CD 20⁺-335⁺ is the first dryer to use the revolutionary Cerades™ desiccant developed and patented by Atlas Copco. Compressed air is channeled straight through the solid desiccant, as opposed to pushing its way through loose desiccant beads. As a result, you enjoy:

• Lower energy costs and a minimal pressure drop thanks to the

straight, no-resistance air flow.

• Better air quality and longer service intervals because Cerades™

lasts longer than loose desiccant, which decays significantlyover time.

• Environmental and health protection, lower operational costs,

and less downtime as Cerades™ eliminates desiccant dust and the need to filter it out to reach ISO 8573-1:2010 Class 2 for

particles.

• Trouble-free installation and continuous operation as Cerades™

can be mounted horizontally.

• A smaller dryer size as Cerades™ can handle a higher air flow.

2 , High-efficiency operation

Designed to perform reliably at continuous operation of 100% airflow, whereas most dryers on the market are only built to work at 70% to 80%. This includes a constant pressure dew point of -20°C/-5°F, -40°C/-40°F,

-70°C/-100°F* as standard. The pressure dew point can

also be adjusted for seasonal or application changes.

*-70°C/100F uses molecular sieve desiccant

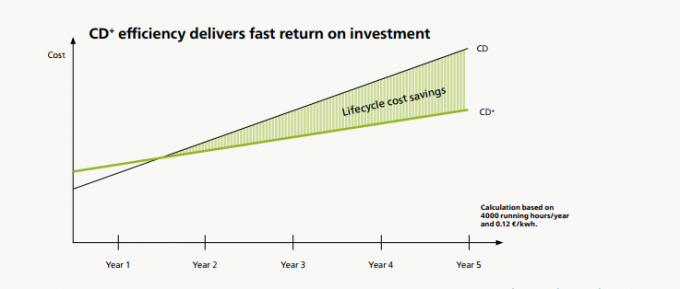

3, Advanced energy savings

• Up to 70% less pressure drop compared to previous

model.

• 15% purge air reduction compared to the standard

CD model.

• Optional Dew Point Dependent Switching. The

dryer will only switch to the next tower when the desiccant is saturated, as measured by the dew point sensor. During this cycle time extension, the dryer consumes no purge air, resulting in asignificant reduction in energy use.

• Dew point can be set to the requirements of your

application to reduce energy consumption.

4, Unique manifold/valve design

• Large pipe diameter minimizes pressure drop for advanced energy savings.

• Electronically operated 3/2 valve reduces risk of breakdowns and offers reliable control duringairflow fluctuations. With this new design, vessel switching operates unfailingly even in rough conditions.

• Service openings ensure easy service of the moving parts of the valve system.

5, New silencing design

Innovative silencing system with large front silencer provides quiet performance with minimal pressure drop.

6 , Advanced control and monitoring system

• State-of-the-art Elektronikon® Touch control and monitoring system with warning indications, dryer shutdown and maintenance scheduling.

• Standard SMARTLINK remote monitoring to maximize air system performance and energy savings.

• Pressure dew point sensor for Dew Point Dependent Switching standard with Elektronikon® Touch and optional with DC1 controller.

7, Service and maintenance-friendly

• Compact Cerades™ blocks allow for quick and easy maintenance.

• Loose desiccant decomposes over time, releasing a fine dust into the air system, which requires extra filtration and maintenance. This dust is also a health and environmental hazard, as it circulates in the ambient air during desiccantreplacement. Cerades™ eliminates this dust problem.

8 , Integrated inlet filter

• A highly efficient UD⁺ pre-filter prevents oil contamination to increase desiccant lifetime.

• For mounting directly on the inlet of the dryer for low pressure drop.

• Easy to assemble and maintain. No extra piping and filter connections are required.

• An after-filter is not required to reach ISO 8573-1:2010 Class 2 for particles. To reach Class 1,a PDp⁺ filter is recommended.

9 , Nozzle purge set

Offers flexibility in optimizing regeneration pressure. Standard is 7 bar; 4-bar, 5.5-bar, 8.5-bar, 10-bar,11.5-bar, 13-bar and 14-bar nozzles come as separate parts. 10 Advanced options

• Pressure dew point sensor for DC1 controller.• Wall mounting kit.

Technical Specifications

| Type |

Pressure dew point |

Inlet capacity 100 psig |

Pressure drop excluding filter | Filter size | Dimensions(L x W x H) | Weight | |||||||

| Pre-filter | |||||||||||||

| °C | °F | l/s | m 3 /h | cfm | bar(e) | psig |

0.01 μm 0.01 ppm |

1 μm | mm | inch | kg | Ibs | |

| CD 25+ | -70 | -100 | 25 | 90 | 53 | 0.04 | 0.51 | UD25+ | DDp35+ | 394 x 807 x 1495 | 15.5 x 31.8 x 58.9 | 124 | 273 |

| CD 35+ | -70 | -100 | 35 | 126 | 74 | 0.07 | 1.06 | UD45+ | DDp35+ | 394 x 827 x 1495 | 15.5 x 32.6 x 58.9 | 135 | 298 |

| CD 45+ | -70 | -100 | 45 | 162 | 95 | 0.13 | 1.93 | UD45+ | DDp50+ | 394 x 847 x 1835 | 15.5 x 33.3 x 72.2 | 158 | 348 |

| CD 55+ | -70 | -100 | 55 | 198 | 117 | 0.04 | 0.62 | UD60+ | DDp70+ | 564 x 847 x 1495 | 22.2 x 33.3 x 58.9 | 208 | 459 |

| CD 65+ | -70 | -100 | 65 | 234 | 138 | 0.06 | 0.91 | UD100+ | DDp70+ | 564 x 877 x 1495 | 22.2 x 34.5 x 58.9 | 224 | 494 |

| CD 90+ | -70 | -100 | 60 | 324 | 191 | 0.13 | 1.93 | UD100+ | DDp130+ | 564 x 907 x 1835 | 22.2 x 35.7x 72.2 | 266 | 586 |

| CD 110+ | -70 | -100 | 110 | 396 | 233 | 0.08 | 1.16 | UD140+ | DDp130+ | 734 x 907 x 1495 | 28.9 x 35.7 x 58.9 | 320 | 705 |

| CD 130+ | -70 | -100 | 130 | 468 | 275 | 0.12 | 1.78 | UD140+ | DDp130+ | 734 x 907 x 1835 | 28.9 x 35.7 x 72.2 | 375 | 827 |

| CD 165+ | -70 | -100 | 165 | 594 | 350 | 0.11 | 1.62 | UD180+ | DDp170+ | 929 x 907 x 1835 | 36.6 x 35.7 x 72.2 | 477 | 1052 |

| CD 195+ | -70 | -100 | 195 | 702 | 413 | 0.16 | 2.26 | UD220+ | DDp210+ | 929 x 907 x 1835 | 36.6 x 35.7 x 72.2 | 477 | 1052 |

Reference conditions BD + : Performance data per ISO 7183:2007.

Compressor air inlet temperature: 35°C/100°F.

Inlet relative humidity: 100%.

Reference conditions BD + ZP (Zero Purge):

Performance data per ISO 7183:2007.

Ambient air temperature: 25°C/77°F.

Ambient air relative humidity: 60%

Contact Person: charliejtt

Tel: +8618029182863